About Us

TSSC AUSTRALIA

Our mission is to contribute to society through sharing Toyota Production System (TPS) experience and know-how with Australian organisations to help strengthen the local community, and sustain a legacy for our 54 years of local manufacturing.

The Toyota Production System Support Centre, known in-short as TSSC Australia, was established in 2016 based on a model shared from TSSC North America.This model is designed to give back to the local community by sharing Toyota’s manufacturing experience and know-how with local organisations committed to organisational improvement. Since then, we have supported many Australian non-profit and general industry companies apply TPS to their own operations to help them address their own unique business needs. Our team is made up of passionate team members, skilled and experienced in applying TPS, and eager for the challenge to help others.

TSSC Australia works closely with the Toyota Community Foundation. We are a department within Toyota Motor Corporation Australia and a part of the global Toyota family lead by Toyota Motor Corporation in Japan.

Sharing Ideas

TO FIND BETTER WAYS OF DOING THINGS

Our years of manufacturing experience have taught us that small improvements can make a big difference – and our Australian team members use this philosophy to find better ways of doing things each day. Over time, we’ve learned that this approach can help other organisations, too.

For more than a decade, we’ve shared our knowledge — known as the Toyota Production System — with other manufacturers in our supply chain to enable them to develop better ways of doing their day-to-day work. Together, we find solutions that make them more productive, maximise available resources, or improve quality and safety. In recent years we have expanded our focus to work with a wide range of organisations to share the Toyota philosophy with more people and organisations.

Sharing our ideas this way makes it possible for our partners stay competitive and preserve jobs or support more people in need — and that benefits all of us.

Our national partners include organisations in a variety of industries including finance, healthcare, manufacturing and the non-profit sector.

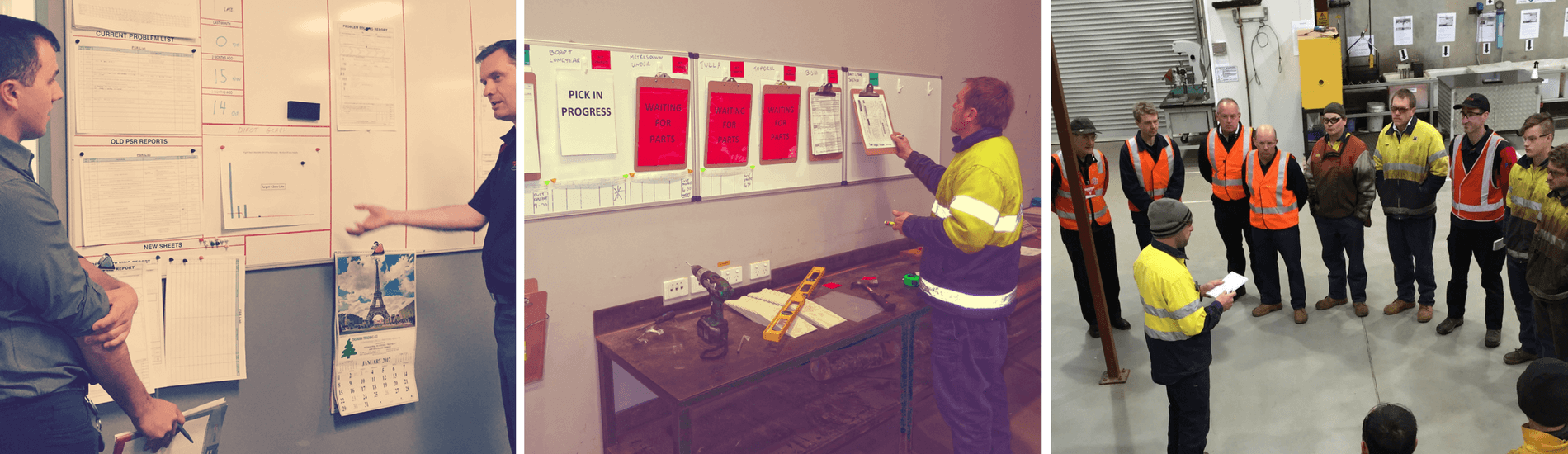

When our partners tell us about their challenges, we don’t know all the answers right away. What we do know is that we have to roll up our sleeves and meet them on the “shop floor” to learn more. This gives us an up-close look at how they operate so we can work together to find solutions. Once our partners learn our approach, we encourage them to make it their own and use it every day.

We’re always excited to have businesses in any sector invite us to work with them. If you’re interested in partnering with us or just want to learn more about our approach, please contact us here.

Martin Nelson

General Manager, TPS Operations

The Toyota Production System

TPS

The Toyota Production System – also known as TPS – is an organisational culture that consists of three key elements described in TSSC America’s video:

Toyota’s Philosophy

Toyota’s philosophy is customer first, people are our most valuable resource, continuous improvement and shop floor focus.

Managerial Role

Leaders inspire and develop people to surface and solve problems to improve performance.

Technical Tools

Use appropriate TPS Tools and Practices to achieve Just-in-Time production and Built-in Quality (Jidoka)