About Fruit2Work

Fruit2Work are a not-for-profit social enterprise that delivers fruit, milk and pantry items to workplaces around Melbourne. They believe that everyone deserves a second chance, and exist to provide jobs for those impacted by the criminal justice system. In this way, their employees are supported to reintegrate into the community, and their lives and families can be transformed.

The Contribution to the Community

After leaving the justice system, it is difficult for someone to obtain employment due to their criminal history. As part of the Fruit2Work program, transitional employment is offered, giving them the skills and confidence to make the transition to full-time employment. Fruit2Work has a 100% success rate in the last three and a half years, with no employee going back to prison. Considering that the recidivism rate in Victoria within the first two years of being released is 47%, this is an amazing achievement.

Business Need

Fruit2Work’s demand was growing rapidly, making it more difficult to provide quality services to current and future customers. Their DIFOT (delivery in full on-time) was at risk as they were unable to deliver the products within each customers specified delivery window.

“We create fresh opportunity for people with lived experience of the justice system”

Improvement Strategy

Having encountered many challenges, Fruit2Work sought assistance from TSSC to improve their processes. In the course of the project, TSSC assisted the team to implement Toyota Production System (TPS) tools to meet the following objectives:

Having encountered many challenges, Fruit2Work sought assistance from TSSC to improve their processes. In the course of the project, TSSC assisted the team to implement Toyota Production System (TPS) tools to meet the following objectives:

On-Time Delivery

- Visualised the current delivery situation based on the delivery area, route, customer window and other factors, assisted in understanding the availability of delivery windows for new customers.

- Identified and removed overburden from the drivers through the application of Heijunka.

- Established a standard loading method to ensure that the first delivery was made on time.

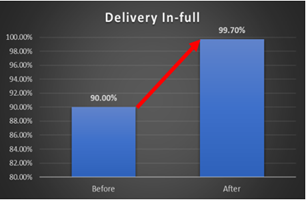

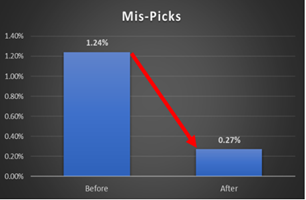

In-Full Delivery

- Build-in-quality to the picking process to avoid mis-picks.

- Developed a standard packing process in order to prevent defect outflow to customers.

Results

Fruit2Work achieved remarkable results by the end of the project. Not only did they successfully complete the project initiatives but have also gained valuable experience and learning in how to apply the Toyota Production System.

|

First delivery on-time improved from 86.96% to 98.8% |

Delivery in-full improved from 90% to 99.7% |

Mis-picks reduced from 1.24% to 0.27% |

Just-In-Time

Provide the customer what is needed, in the amount needed, when is needed?

Jidoka

Building in Quality at the process

Heijunka

Levelling out the workload to reduce overburden