Mieruka

How to see problems

Kanban

Tool for regulating production & stock levels

Standardised Work

Orderly & effective method of production (centred on human movement)

GenU operates within the community services sector, supporting people with disability, the disadvantaged, and the aged. TSSC had previously worked with genU to improve delivery of home care services, and the team reached out again to Toyota for support.

Veggie Processing operates within genU as an Australian Disability Enterprise (ADE), providing employment for people with disability in a supported environment. The Veggie Processing team were experiencing difficulties in managing unprecedented customer demand, which could only be managed by engaging additional skilled labour and management overtime hours.

One key element of TPS philosophy is customer first: the idea that any process should ensure the downstream customer as well as the end user’s needs are met.

Partnering with genU, the TSSC team saw the opportunity to rapidly increase the supported crew’s skill diversity and maximise community impact by enabling more of the work to be done by those with a disability.Through application of Toyota Production System tools and problem-solving methods, the local team worked with TSSC members to:

• Grow the supported crew’s skills through development of internal trainers and use of very clear and easy-to-use work standards

• Reduce management burden, and allow smoother processing of orders, through the use of visual tools for the crew to self-manage their work

• Optimise the timing of order processing and raw material stock management by implementing visual controls and a Kanban system

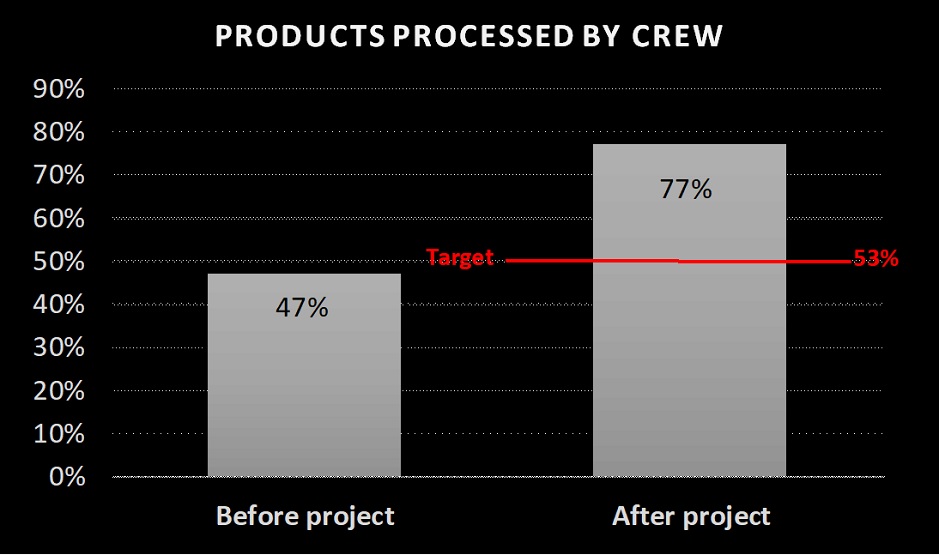

From the improvements, the range of products crew were able to process increased by 30%. Management burden also significantly decreased, reducing the need for excessive overtime hours. Through this project and partnership with Toyota, the Veggie Processing team were able to increase their social impact, growing their business to provide even more opportunities for disabled members of the community.

How to see problems

Tool for regulating production & stock levels

Orderly & effective method of production (centred on human movement)

494 Grieve Parade, Altona North VIC 3025

1300 TSSCAU (877228) | tssc@toyota.com.au